CNC Horizontal Milling Frequently Asked Questions

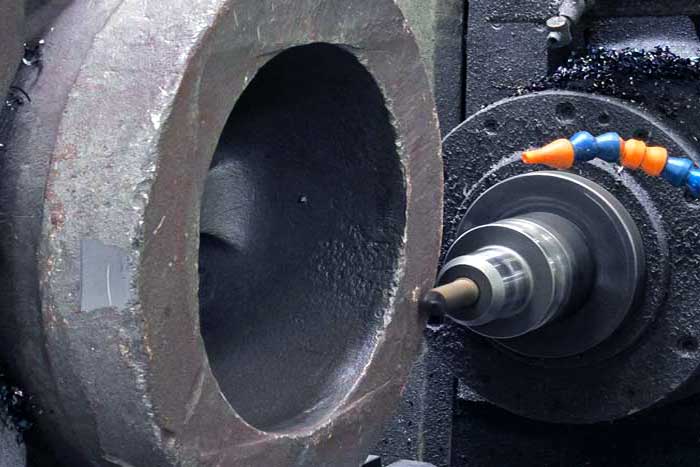

Horizontal milling is ideal for large or heavy components, deep pocketing, precision bores, and multi-side machining where rigidity and clean cutting are important.

It’s commonly used when parts require accurate features on multiple faces without excessive repositioning.

H & M Machine Inc provides CNC horizontal milling in Greendale, Wisconsin,

serving Milwaukee County, Southeast Wisconsin, and manufacturers across the Midwest.

We support large-scale machining, boring, and multi-axis work with consistent, production-ready results.

Yes. Our shop includes a CNC full four-axis horizontal machining center, and we also run a horizontal boring mill with a built-in rotary table.

These capabilities help reduce setups and improve accuracy for complex parts.

Absolutely. We program with Virtual Gibbs, so sending DXF files can speed up quoting and help us plan efficient machining paths.

If you have drawings, material specs, quantities, and tolerance requirements, include them for the most accurate estimate.

In most cases, we can provide a horizontal milling estimate within 2–3 business days

after reviewing your drawings, material requirements, quantities, and tolerance specifications.

Request a CNC Horizontal Milling Quote

Need deep, clean cuts and reliable multi-side machining? Call H & M Machine Inc for CNC horizontal milling in Greendale and the greater Milwaukee area. We’ll review your DXF files, drawings, and specs and provide a clear estimate with realistic lead times.

What Customers Say About H & M Machine Inc